Plastics : FLAWSCAN™ 4000 Plastics

Advanced online Inspection System for Plastics

FLAWSCAN™ 4000 prevents defective material from reaching your customers.

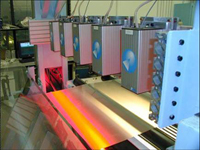

FLAWSCAN™

system features proven, state of the art optical surface inspection technology

utilizing high speed image sensors and innovative illumination to provide real

time image processing. This combination delivers reliable defect detection

at required throughput speeds. More reliable than human inspection and adapted

to match your process conditions and inspection requirements, FLAWSCANTM

makes visible what is not at production speed.

FLAWSCAN™

system features proven, state of the art optical surface inspection technology

utilizing high speed image sensors and innovative illumination to provide real

time image processing. This combination delivers reliable defect detection

at required throughput speeds. More reliable than human inspection and adapted

to match your process conditions and inspection requirements, FLAWSCANTM

makes visible what is not at production speed.

FLAWSCAN™ 4000 delivers the highest quality defect images, ensuring reliable data for optimizing the production process.

Each defect is analyzed and classified. The images are displayed and archived in predefined categories, such as: (Distortion, Gels Insects, Contaminant, Coating Void, Scratch etc…). Classification is performed using a state of the art artificial intelligence engine for a more reliable classification and a very intuitive system configuration.

FLAWSCAN™ 4000 provides a “window into your manufacturing process” to enable increased yield and process improvement.

Providing real time feedback on your process, FLAWSCANTM enables you to respond quickly to process upsets. Post processing of inspected rolls enables the operator both to easily retrieve inspection data at the slitting station and the removal of unacceptable product without wasting important production time. Thanks to reliable statistical information on your process, FLAWSCANTM ensures a better understanding of the source of your defects, to assist in preventing their future reoccurrence. i2S assists in maximizing your ROI.